by Russell Wood

Selecting the right profile and material for a rod seal requires considering many different factors. Even the most common hydraulic seal functions and cylinder designs demand knowledge about how rod seals work and what specific applications they may be used for in order to avoid equipment failure. Before replacing your next rod seal, make sure to familiarize yourself with some basic information so you can select the right seal, the first time.

What Does a Rod Seal Do?

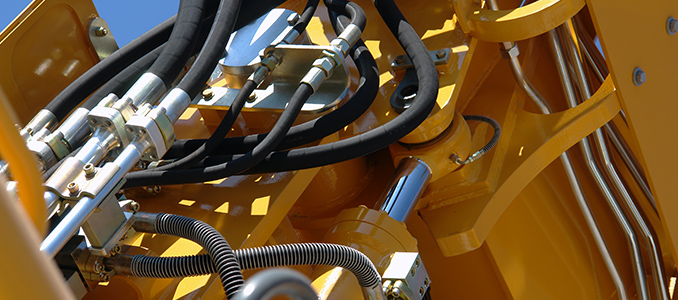

Rod seals are key supporters within hydraulic cylinders. They manage fluid sealing and, in doing so, help maintain the hydraulic cylinder’s performance capacity. When a rod seal fails, loss of system pressure leads to system failure. In addition, fluid escaping the cylinder can lead to environmental contamination.

What Details Do I Need To Consider?

Common considerations for rod seal selection include:

- Fluid Pressure – Having a full understanding of the fluid pressure range of your rod seal application, as well as a sense of how often a pressure spike might occur — and the severity of the spike — can affect the profile of your rod seal.

- Fluid Temperature – Temperature also can affect your rod seal profile. Knowing the range of the fluid temperature, as well as the cylinder assembly — both when in operation and at rest — will help your seal solution partner recommend the best material for your case.

- Stroke Speed – A seal is rated for a maximum stroke speed, depending on the profile and material. Knowing the speed will allow you to choose the profile best suited for the application.

- Fluid Type – Hydraulic cylinders use varying fluids depending on their applications. Knowing the type of fluid (e.g., petroleum-based, glycol-based, water-based), as well as the viscosity of the fluid, will determine what rod seal profile is best for you.

- Size and Dimensions – Knowing the groove dimensions (including tolerances) in which your rod seal will operate, as well as details like stroke length and extrusion gap, will ensure the proper fit and performance of your seal.

- Cylinder Application – The environment in which the cylinder operates is critcal to the choice of rod seal you use. Being aware of external and environmental influences (e.g., temperature and possible contaminants) can also help determine which rod seal is best for you.

While these tips are helpful for anyone sourcing a new or replacement rod seal, there are also times when customized solutions are required for optimum seal — and, in turn equipment — performance. Engaging a company with experienced engineering professionals, such as H&D Distributors, can make both common rod seal replacement or development and custom rod seal selection a smooth and seamless process.

Want to learn more about rod seals and how to master the hydraulic seal specification process? Download our “Expert’s Guide to Hydraulic Seal Selection.”

Or, if you’re ready to specify, contact us and we’ll put our 45+ years of collective experience developing sealing solutions to work for you!

About H&D Distributors

For over 40 years, H&D Distributors has provided expert sealing solutions for OEM and MRO customers in various industries where productivity is key, including hydraulics, oil and gas, and semiconductor. Leveraging in-house engineering and testing expertise, exceptional customer service, and a global network of top sealing manufacturers, H&D's goal is to deliver solutions for its customers’ pressing sealing challenges expertly, accurately, and on time.

|

About Russell WoodRussell Wood, General Manager at H&D, leads the H&D Technical Team as well as its Inside Sales Team. He has over 30 years of experience in the seal industry. |